|

Page 2 The project begins |

|

|

It got obvious that the driver's side rear window wouldn't fit in the skewed opening. After a few days of measuring and looking for a reason to this problem the B-pillar was adjusted. At this point all the windows openings were checked and adjusted.

|

|

The rear windows and quarters got about the same treatment as the doors: A top frame, and a built midsection to house the window crank mechanism. The bottom framing and wheel tub still on the to do-list. |

|

|

|

Work commenced on the rear pillar framing. The shrinker/stretcher came in handy here. |

|

The rear window was framed too, after the outer bodypanels that previously had been nailed together were welded. As the rear window opening is curved both top and bottom, it made for some interesting sheet metal work. |

|

|

In this pic the inner structure can be seen. The left door is getting its framing done at this stage. |

|

The old six cylinder flathead was yanked to make for better access to the front of the body. |

|

|

|

At this point it became apparent that the door openings weren't sized correctly, and also that the A pillars were rotated slightly wrong, so that the hinges were binding on both doors when they were pushed shut.

|

|

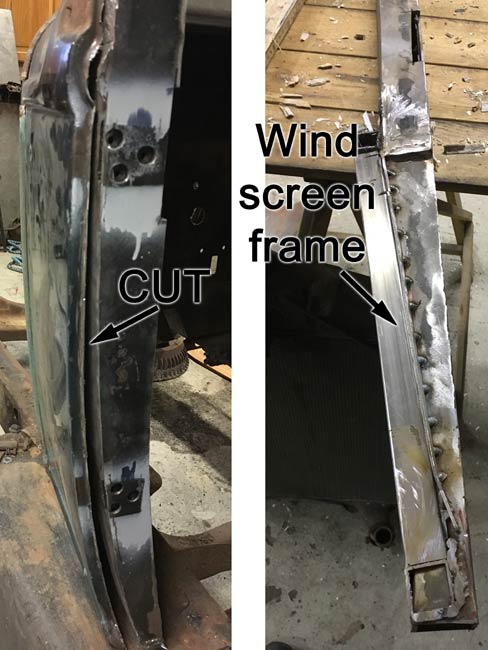

The whole windshield frame was cut out along with some bracing. It took a few deep breaths to get into the mood to cut away most of the work already done. |

|

|

|

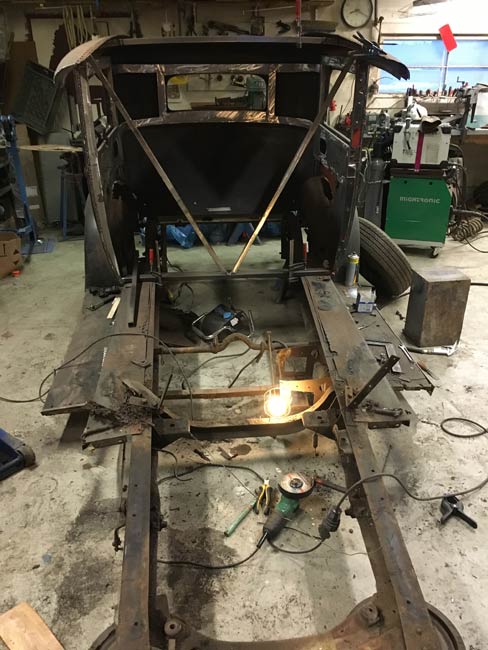

This was all that was left. Not much to show off after almost a year and a half since the project was started. |

|

The A-pillars were mounted to the door hinges. After that the doors were tack welded to the quarter panels, taking care to leave a nice, even door gap. |

|

|

|

Good friend Tomas helping out here, taking a break checking the work so far, after the doors have been tacked to the quarters. |

|

Following this the cowl was tacked to the doors. This was the result of a good day's work. |

|

|

|

The A-pillars and new bracing was welded from the inside, and finally the tack welds that held the doors to the body were ground off. The doors fit nicely now. |