|

Page 2 The project begins |

Something interesting arrived, though, and no way could we keep

away from the shop anymore.

|

|

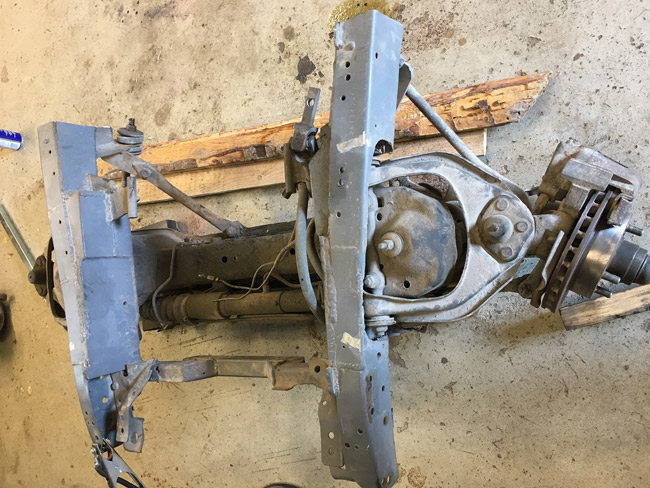

A used stock Mustang II front suspesion was purchased and hauled home. Here it is, just rolled into the shop on its pallet. |

|

The front end had been mounted to some kind of frame previously, so some cutting and cleaning up will have to be done. |

|

|

|

Everything not welded in was removed from the cross member. |

|

A couple weeks later the frame rail pieces were cut away from the cross member, and it was cleaned up and sprayed with some flat black paint.

|

|

it was finally time to get back to the Buick.

|

The doors are as much a wooden structure with an outer sheet metal skin, as the rest of the body. When trying to remove the wood, it's evident that the wooden structure had been built before skinning the door with sheet metal. Some screws were screwed in from the outside with no way to get at them in any other but to saw them off, and some of the wooden parts had to be cut into pieces to get them out. |

|

With all the wood gone, the door is very flimsy, barely able to keep its shape. |

|

|

|

All this wood came out of one door. There will be a bit of work to make a new substitute structure out of sheet metal. |

|

Some kind of mishap has apparently gone down on the right hand side. The B-pillar and most of the quarter panel has gotten back it's original shape, save for some remnants of a dent. As can be seen the door doesn't really fit against the B-pillar A couple of reliefs had to be cut to get the rear of the door back to its approximate original shape. A new piece of thicker sheet metal, 13 or 14 gauge (2 mm) almost a copy of the B-pillar, was cut out and welded to the inside of the rear of the door to make it fit better. |

|

|

|

The first piece of the inner structure trial fitted in the door. It's 19 Gauge (1 mm) sheetmetal and the holes were cut with the plasma cutter. The plasma cuts thin sheet metal fast and easy and the result is surprisingly clean and leaves little grinding work. |

|

This was a problem. The driver's side rear window opening was sqewed, it's obvious in the left pic. The whole body was measured thoroughly to find the reason for this, and then it was time for some massaging, cutting and welding. The result looks about right. |

|

|

|

Now that the door is painted with primer, it shows how empty and simple this thing is. |

|

The top of the door is framed with sheetmetal, as is the rear vertical part. |

|

|

|

Making the midsection of the door took a good deal of measuring and planning. Before this could be welded in, channels for the opening windows had to be made. |

|

The door all done now, the window crank and door lock mechanisms work. It's very rigid and fits in its opening too. |

|