|

Page 2 The project begins |

|

There's supposed to be a bead running along the underside of the door. This filler part was a stamped steel profile, but one was missing, and the other one was so rusty, it was deemed unusable.

|

|

|

|

The new beads were made by rolling a 1" diameter tube to a suitalbe curve, then cutting it into a half and welding it to the edge of the floor. The ends of the tube were capped with 3/16" thick peices of metal, so that the ends could be ground rounded. |

|

The new bead now connects the lower body line between the quarter panel and the cowl. |

|

|

|

Then turning the attention to the top of the door opening, the door jambs were next. One of these were missing too. Some previous owner had gotten one from a four door car, so making two new ones seemed logical. |

|

Here it is, welded in and ground. The weld seam is 1/4" above the door opening. |

|

|

|

Profiles to attach both top and bottom weather seals were made. Seal in place here. |

|

|

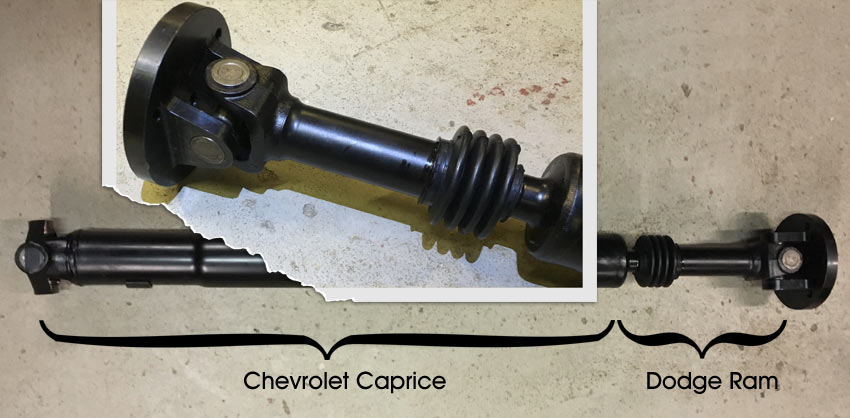

The propshaft is done. A very cool billet front yoke was CNC machined out of a piece of 8-3/8" diameter axle. It fits the output shaft of the ZF transmission.

|

|

Stainless tubing bent to a 62 degree angle were ordered. 12 of them. |

|

|

|

Flanges drawn in CAD, and laser cut

|

|

Exhaust flanges polished |

|

|

|

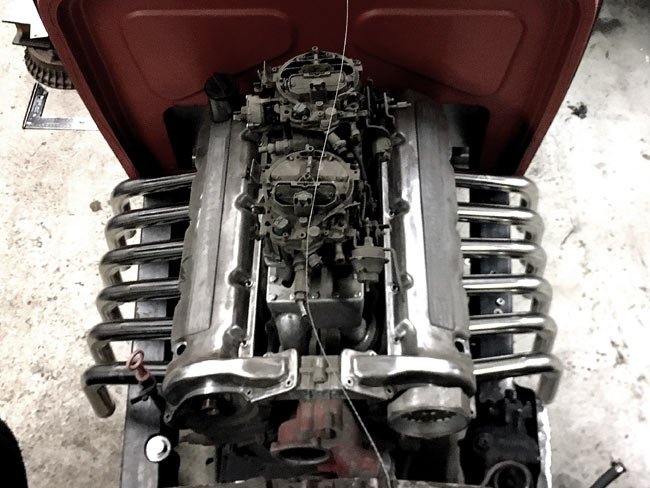

Exhaust primary tubes tacked to the flanges. |

|

The headers give the engine a new precense. The tall and skinny engine really needs this. |

|

|

|

Two of these Air-Maze oil bath air cleaners were bought at a swap meet several years ago, actually the first parts acquired for this rod project. |

|

Annoyingly enough, the carbs are too close to eachother to allow for the huge air cleaners. The solution was to cut them and weld them into a single unit. Surprisingly enough this still looks pretty good, so it's considered a success.

|

|

|

|

The primary exhaust bends are back from welding, so now it's time to make the collectors. There will be four of these three into one flat collectors. This type of collector was chosen because there is limited space / ground clearance under the frame. The ends of the three primaries here are all the same cross sectional area as the round pipe they come from. |