Ok, so the Rod's ready and now all you have to do is enjoy, right?

At first the Essex was a real pain to drive over about 40 mph.

what's the use of a car like that?

Not much, but it can be improved, and here are

a few improvements that have been made and that should be made.

|

It was obvious from the first few test drives that there was something very wrong with the handling. Over about 40 mph the car was a beast to drive. This was a big disappontment and took away most of my enthusiasm.

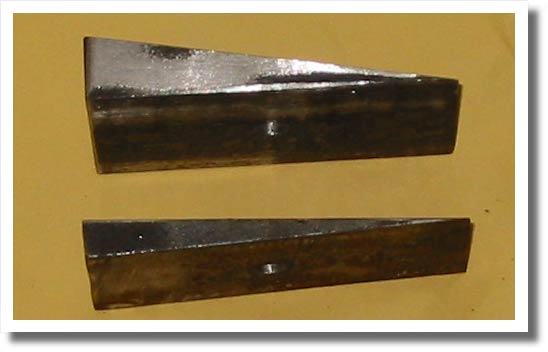

A lot of rods seem to use a lot more caster, and after some research more caster seemed like a cute that might work. New caster wedges were aquired. |

|

This pic shows the front axle with new, stiffer spring leaves, the new wedge between the spring and axle (not easily seen here) and on the top of it all, an "anti brake torque leaf". |

|

|

While the new caster wedges and stiffer leaves improved handling and driveability immensly, allowing for speeds over 60 mph, it became obviosus that braking, besides tugging at the drag link, also made the rod more or less uncontrollable, and very unpleasant to drive while braking. |

|

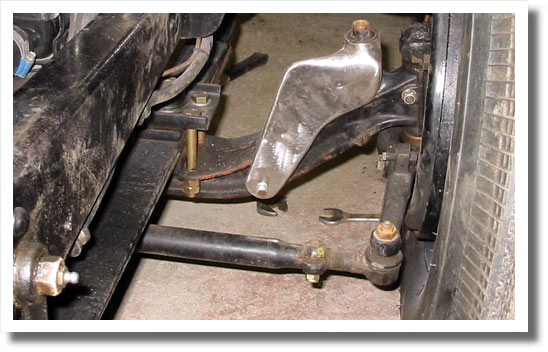

The front mount is being fabricated here. |

|

After some more welding and a lot of grinding the front mount looks like this. |

|

|

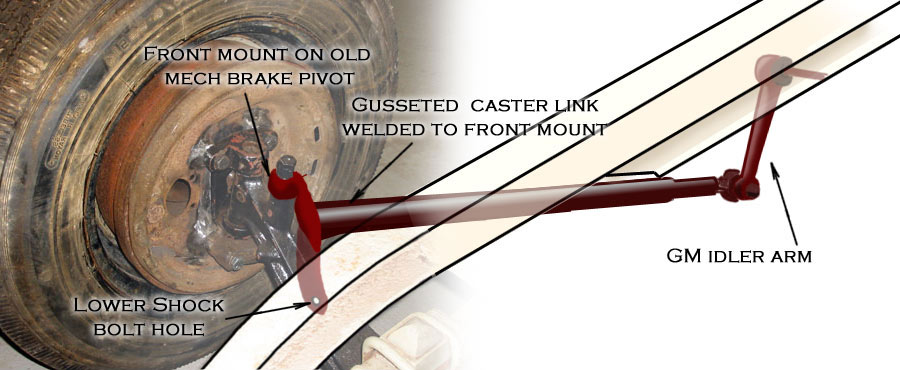

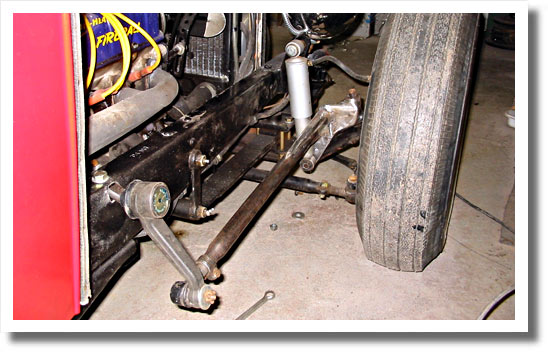

A GM idler arm was mounted to the frame and the link welded to the front mount with generous gussets. |

Here's an explanation to the idler arm setup.

|

Ford style front suspensions with the original whishbone, split wishbone, and hair pins articulate in this fashion. |

|

|

The caster link has to be articulated in the rear to prevent binding. |

|

This animation is pretty much self explanatory... |

|

|

In practice the caster bar didn't work that well. Yes it prevented the front axle to twist like crazy, but it was also made from too flimsy materials, and thus bent a bit when braking hard. This, of course, left the caster angle in a less then perfect position. The bar was removed, and the problem was ignored. |