Fuel injection conversion continued.

|

Everything has worked out pretty nicely regarding the engine transplant, and here's more.

What was even better was that the old fan shroud is a good fit too, which is a result of pure luck with the height of the new engine mounts. |

Most of the accessories and stuff bolted to the new engine seem to fit pretty nicely in the Chieftain, but the drivers side exhaust manifold in an exception. |

|

|

A couple days of welding and grinding resulted in this exhaust manifold.

The swan neck look of the collector pipe is to clear the floor mounted brake pedal.

The thingy with a wire attached is the O2 sensor (Lambda). |

The right hand side exhaust manifold fits nicely in the Chieftain, and the only modifications are plugged AIR fittings and a squirt of Dinitrol aluminum heat resistant paint. |

|

|

To convert the fuel tank to EFI use, a return line has to be connected to it. The solution was to drill a hole and mount a fitting for a 3/8" hose in the filler neck. |

All the hoses to the radiator has been connected including the transmission fluid lines, the radiator and fan shroud fully mounted. |

|

|

As the Firebird had electric fans and the Chieftain will run a belt driven fan, a new connection between the throttle body and the mass air flow sensor (MAF) was fabricated from sheet metal. The Firebird air cleaner has been stripped of its plastic and gotten a new mount, and is connected directly to the MAF. |

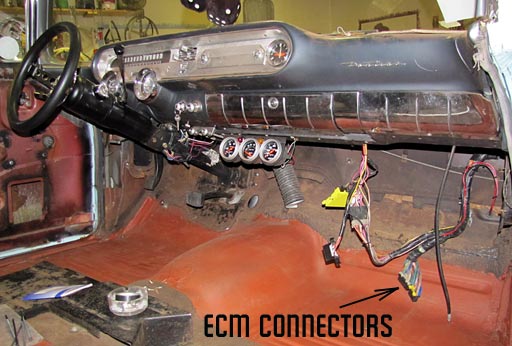

More or less all of the engine management system is connected now, and only a couple wires to the coil and alternator remain to be hooked up. |

|

|

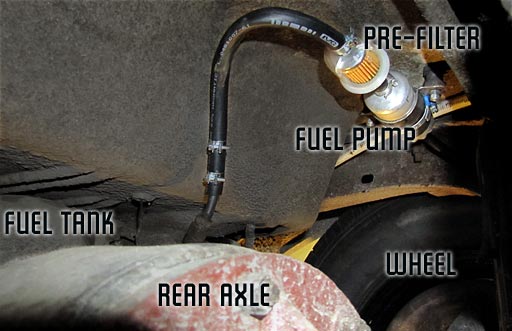

The TPI system needs a different kind of fuel delivery than a carbureted engine, the main difference is in that an electric high pressure fuel pump and a return line is neded. Here a Bosch pump is mounted under the trunk floor just in front of the fuel tank. |

As good as everything else fit, so did the wiring to the ECM connectors. |

|

|

Not really a part of the injection system, but the lowering blocks were fabricated and mounted at this time. They are offset about 3/8", or about 9 millimeters. They move the axle rearwards, the reason being that the prop shaft came out a smidgen too long. |

A problem well known among guys working with tri-five Pontiacs is that the driver's side exhaust pipe has to go through the frame and around the under seat heater. To the right the fuel pump wire in its blue rubber hose can be seen snaking its way along the frame. |

|

|

New, big and hopefully suitably loud pipes. |

After changing oils and filters, flushing connecting and testing the fuel lines for leaks, the time came to fire the TPI engine up. |

|

All the to do-lists are nearly completed, as can be seen in ths pic. |

Here the Trans Am is seen shod in new American Racing wheels, no less, leaving on a trailer with its new owner. |

|

|

A few days after the engine had been fired up, the throttle pedal and wire were fabricated and mounted, and it was time for a test drive. |