The 1957 Chieftain will be converted to fuel injection.

An '87 Firebird Trans Am GTA was bought to act as a donor car.

The 'bird engine features Port Fuel Injection, which seems to be General Motors lingo, and

is the same as Tuned Port Injection.

Lots of new things to learn here...

|

The first few things that have been removed from the Firebird.

On top is the air filter and Mass Air Flow sensor (MAF), and below some "normal" parts, radiator, fans, their relay and a V-belt. |

With the radiator and air conditioning compressor removed, the engine can be seen under the plenum and throttle body (arrow). |

|

|

Ow, what a jumble of hoses! |

Following the electrical harness got me inside the car, and there the Engine Control Module (ECM) was. |

|

|

After removing the alternator I started to remove stuff from the right hand side of the engine. |

Here's the ECM box with the Ignition Control Module on top. |

|

|

The result of a day in the garage. |

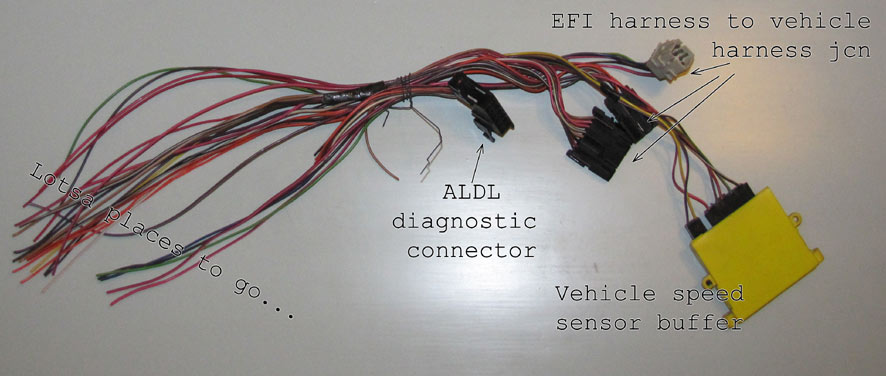

The complete engine control wiring harness. |

|

|

After the interesting work with the engine control harness, it was time for some wrenching. |

The GTA on stilts to provide some work space underneath. |

|

|

Lifting out the engine was easy after removing engine mount bolts, the complete fuel system, including fuel lines, filter, pump and tank. |

|

A few aerosols of Bräkleen and some elbow grease later the engine was ready for some black and silver paint. |

EFI harness to vehicle harness junction connectors seen here are to be connected to the existing electrical system in the Chieftain. |

At long last the Firebird got pushed out, and the Chieftain pushed in. The starter is so bad, that it wouldn't crank fast enought to fire.

Looking forward, the biggest problem anticipated at this time is the drivers side exhaust manifold, which isn't exactly of a perfect design for this application. |

|

|

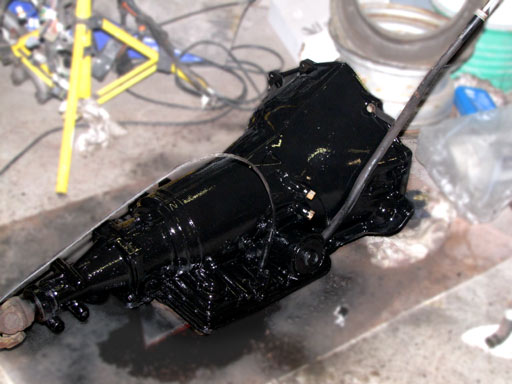

This is what the three speed manual transmission looks like. |

The old engine on the floor after a long day of wrenching. |

|

|

The new engine will have lots of room here as it's a lot smaller than the old Pontiac engine. |

Next up will be to mount a power steering box in place of this manual box. |

|

|

Here the new engine is hoisted into the engine bay for the first time. |

The oil pan of the 1987 Firebird engine fits perfectly! An inch or so of space is all we need. |

|

|

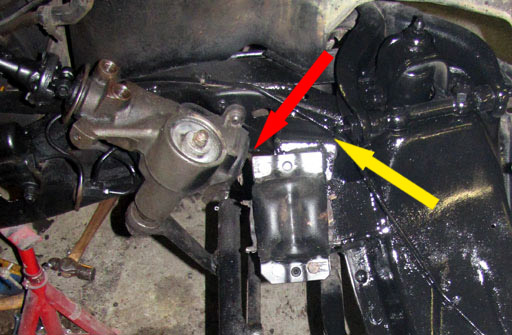

In order to mount the transmission under the '57 Pontiac, the Firebird crossmember had to be lengthened some 3". Holes for mounting bolts were drilled in the X-member. |

The engine had to come out to make room for finish welding the engine mounts, and here they are with a coat of The transmission in this pic is a TH-700R4, also out of the Firebird |

|

|

The Firebird engine mounts proved to be in the exact right position! See how close to perfect this is:

The distributor is about one inch from the fire wall.

|

More on the TPI conversion here.