As this car has torsion bar suspension, it's very easy to lower,

just a matter of turning the adjusters till the height is right.

|

The lowered front end makes the Dodge look much meaner.

|

|

|

|

The rear view is improved too, the result a kind of an eighties look. |

|

The traditional may day family photo, minus big brother, who's away at this time.

|

|

|

|

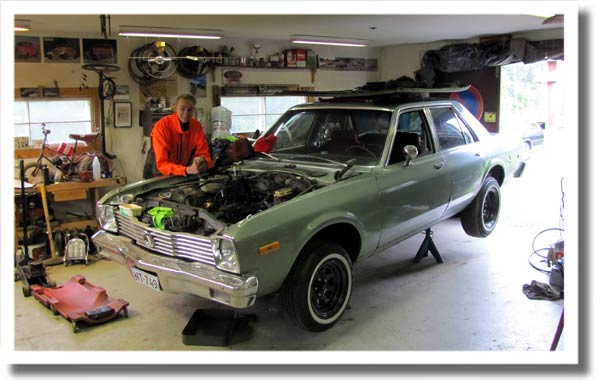

The Dodge on the jack stands, the engine unbolted from both the car and the transmission, save for a couple bolts to keep it in situ till the hoist is put in place. |

|

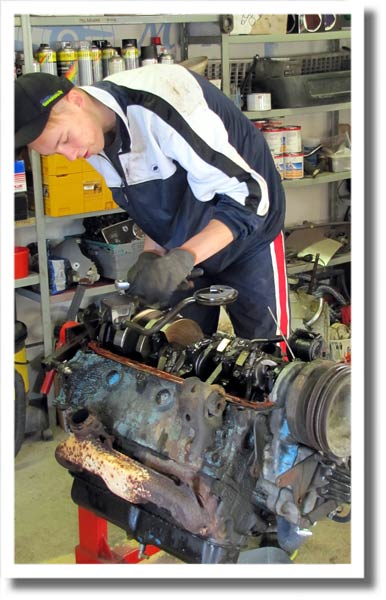

After the engine hoisted out, it was bolted to an engine stand and the oil pan was removed.

|

|

|

|

All the oil and coolant drained out of it, the engine was turned upside down and the Oli pump removed.

|

|

The innards of the oil pump looks about as worn and ground as one would expect, considering the sludge in the bottom of the crank case. |

|

|

|

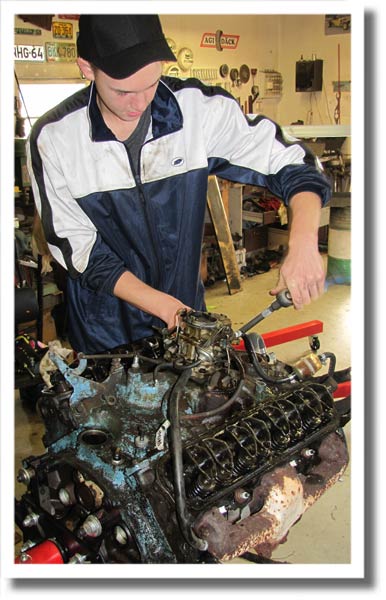

After turning the engine right side up it was time for the two barrel intake to go. Hopefully for the last time, as we have a four barrel intake off a 340 cube engine.

Then the exhaust manifolds were unbolted, the rocker shafts, pushrods and lifters came out, followed by the heads. |

|

|

The lifters (above left) were filled with sludge. All sixteen of them were cleaned out, checked and lubed thoroughly.

|

|

|

A box of parts for the engine arrived. Piston rings, rod and main bearings, oil pump, double roller timing gear and a gasket kit.

|

|

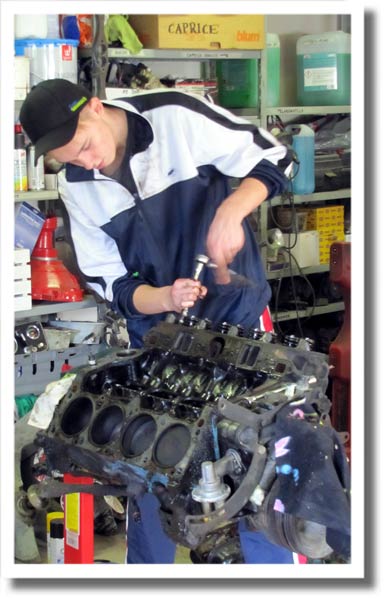

The engine comes together (left). Here the crankshaft, bearings, rods and pistons and rings, the cam with its chain and sprockets are mounted to the block, as are the heads, with new valve seals. The round thing in the front of the cam sprocket is the fuel pump excenter. |

|

|

The oil pan mounted it was time to oil up the engine. Oil was poured into the intake valley,and a tool was made so we were able to drive the oil pump with a power drill. An oil pressure indicator lamp was made, using a battery charger, andwe soon had oil pressure! |

|

After completing the engine build, it was connected to the hoist, the engine stand unhooked...

|

|

|

|

... And the engine lifted high up, over the front of the car, and down into the surprisingly short engine bay. Some wiggling later, the engine was bolted to the transmission with a couple bolts, and the engine mount bolts slid in. |

|

A big thumbs up! |

|

|

|

The original air filter mounted on the four barrel carb after the bottom of the housing was modified to fit. |

|

At long last a testdrive! |

|

Introduction Getting ready to roll 2015 2016 and engine overhaul Summer 2017