First page

Page 2

Page 3

Page 4

Page 5

Page 6

Back to Karkmotuning main page

|

|

Now that the truck was small enough to fit in the garage,time had come to get it inside. As it wouldn't start in the cold weather (almost freezing), it was pushed to the garage door. Lacking someplace to mount a winch to pull it in, a battery was connected, and it pulled itself in using the starter motor. This truck is now officially a hybrid. |

|

To gain access to the floor, the bench seat was unbolted and hauled out. |

|

|

|

|

|

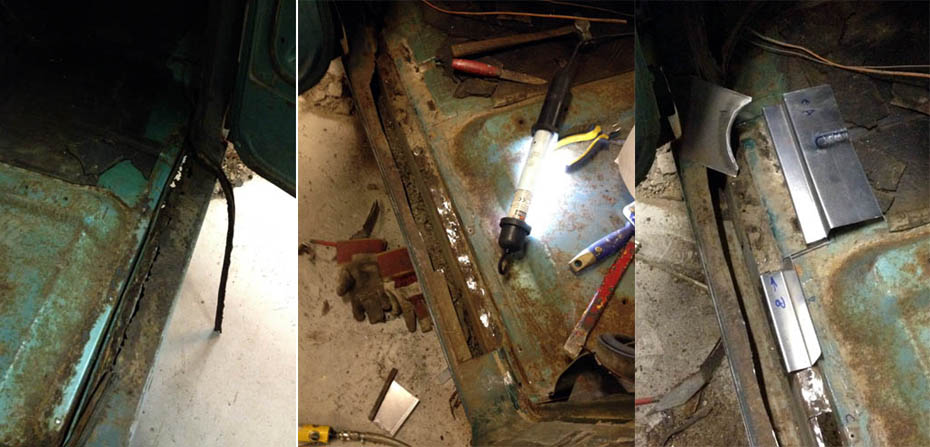

Left: Both sides look like this. The door seal has collected water and dirt from the |

|

|

|

The new floor parts welded in. The rusty top of the inside rocker panel was repaired at this time. If water runs down off the floor, it gets trapped inside the door seal flange. Then gets drained under it, into the rocker, and then the rocker in turn has drain holes to keep it dry. No small wonder it was half full of dirt. |

|

The new home made rocker top was cut to length,and placed where it was supposed to go. Then it's outline was traced on the rocker, and everything inside the trace was cut away. |

|

|

|

When everything was fully welded, the welds were ground down with a grinder, and then finished off with a sanding disk. |

|

A few small tweaks and some cleaning up, and the area was given a coat of primer, still wet in this pic. |

|

|

|

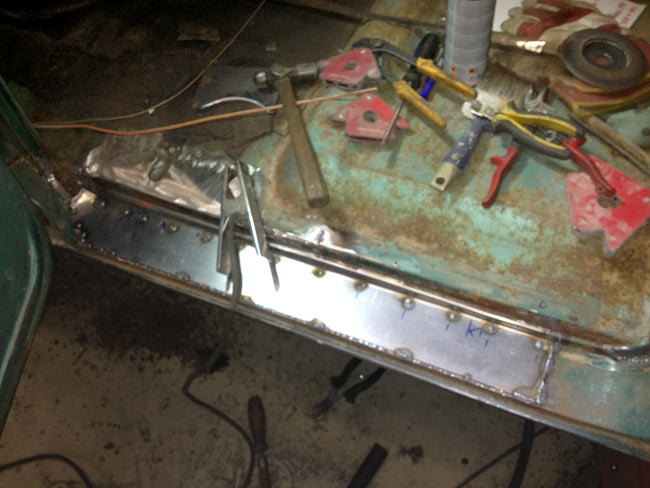

Same work on the right hand side floor and rocker.

My simple sheet metal brake really came in handy here. |

|

The hardest part to fabricate was the front end of the floor/inner rocker which had a complex shape. |

|

|

|

The top of the rocker welded to the outer side, and rosette welded to the inner rocker. |

|

In January pneumonia hit hard, and the truck was put on stay. A lot of work had to be done to our boat in the spring, and nothing further was done to the truck in about a year. Only some parts were collected for the project, The truck was pushed out, as the son's Dodge engine lost the oil pressure, and its engine had to be rebuilt. |

|

Only thing done in the 2016-2017 winter was an ignition system service. New points, condenser, coil, rotor, cap, plugs and wires. It still seemed not to run on all cylinders.

During the Summer 2017 a "new" carb (Carter G2 remanufactured by Holley) was bolted onto the intake, and topped off with a tiny air filter. A brand new fuel pump was also mounted to the engine, and it was soon fired up. |

|

|

|

As the engine ran and the valve cover was off, one could easily see that this engine can'r be used without major surgery. Only seven rockers did their thing. The remaining one was static, so in effect it didn't lift the valve off its seat at all.

Next thing to do is to change the engine, or at least overhaul it, and putin a new camshaft. |

|

Before getting the truck inside, the plans call for some sandblasting of the rear of the frame.

Here, the cab's been covered, and the areas close to the frame taped with duct tape to prevent sand from blasting the sheet metal. |

|

|

|

The sandblaster came in form of a mobile unit.

Very simple. No transporting, and just a very small amount of sand was used, less than 100 kg (200 lbs), so it will easily be hidden in the grass next summer. |

|

The frame got a coat of primer to keep rust away until the frame is ready for paint. There's some repair work to do, some brackets for rear lights and a fuel tank, and maybe some shock absorbers.

|

|

|

|

Back inside again, hopefully getting some more work done this winter than the last couple winters.

Just two rear wheels make for easier access to all of the frame. |