Plans for a Diesel conversion has been in

progress for a few years, and now it's time to do something about those plans and ideas.

The 1980 305 cubic engine is not very effective, burning lots of fuel and still not doing

much, but a diesel should be able to deliver more for less.

This first page will deal with mounting of the engine and transmission.

|

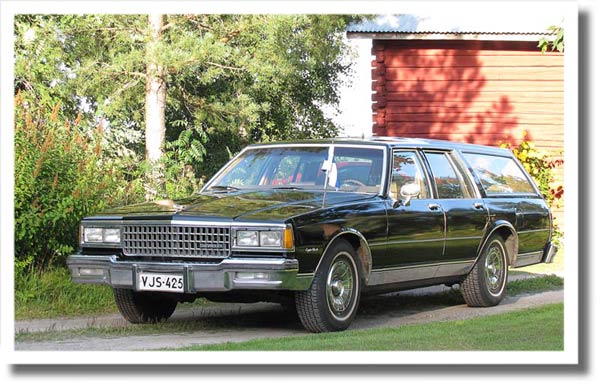

This 1980 Chevrolet is planned to get rid of its V-8 and have an inline six diesel for power instead. The car in it self is in very good condition as it has been working lazily as a hearse until this summer. |

|

|

Is Diesel cheaper? Ten years ago this engine swap would have made real economic sense. Now it's more of a fixed idea, or an experiment, just begging to be done. The car's way too old to make any kind of sense anyway... |

|

Here's a comparison, US to Finnish fuel prices. Prices off the net, the finnish prices converted to US dollars for comparison. |

Premium gasoline in the US (three states checked, CA, WA, TX):

$3.20 and up per gallon Diesel fuel in the US: $3:40 and up per gallon Premium gasoline in Finland $9.06 per gallon Diesel fuel in Finland: $7,64 per gallon |

|

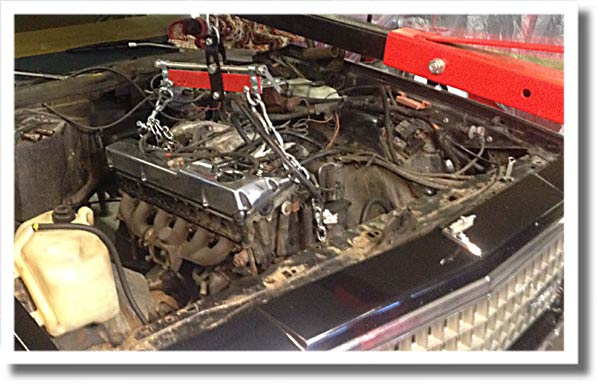

A "rolling" 1983 Chevrolet Caprice was purchased cheap, no engine nor transmission were included in the deal. The car's in pretty good shape, even if the color makes the eyes water.

Here the 350 Corvette engine and TH-700R4 trans is going to be removed and returned to the previous owner.

|

|

|

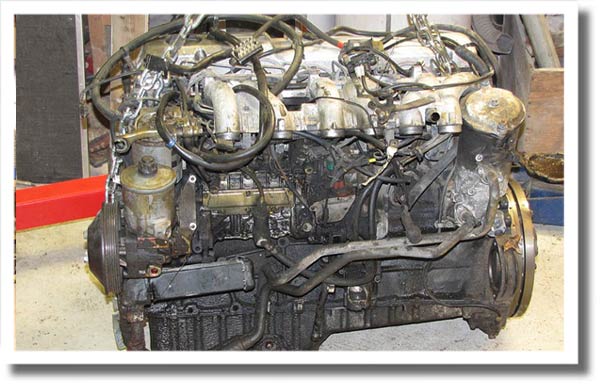

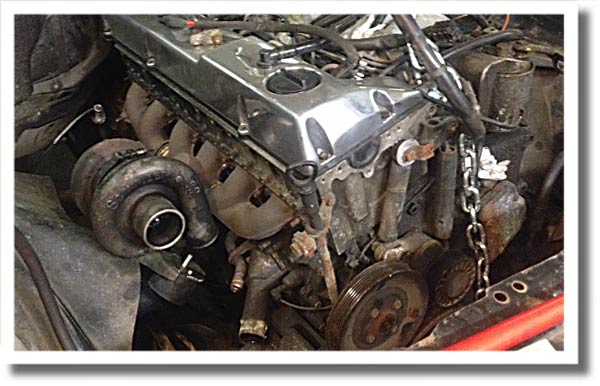

The Mercedes engine was hoisted out of a 1991 Mercedes-Benz 300 D. |

|

There's precious little room in front of the tie rod, so the Mercedes oil pan has to be modified to fit the car. |

|

|

As we had a green Caprice with an empty engine bay in the garage, the Mercedes six was trial fitted into it. |

|

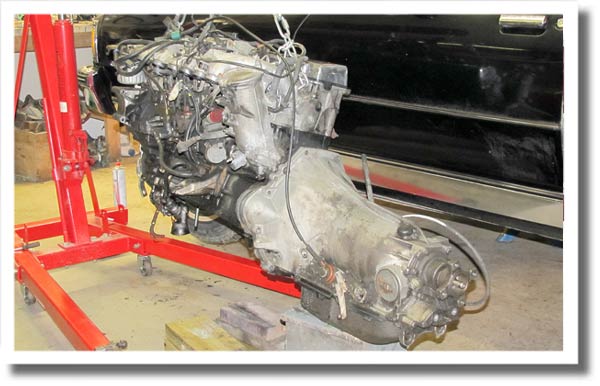

A four speed automatic transmission out of a Mercedes Sprinter van was purchased from a wrecking yard. |

|

|

Today (December 13) the green Caprice was sold with engine and transmission from the hearse, so now we have some funding for the diesel project, and the garage is suitably emptied. |

|

As this engine had a flywheel and clutch, they were removed, and instead the flexplate/starter ring was mounted on the crank shaft. |

|

|

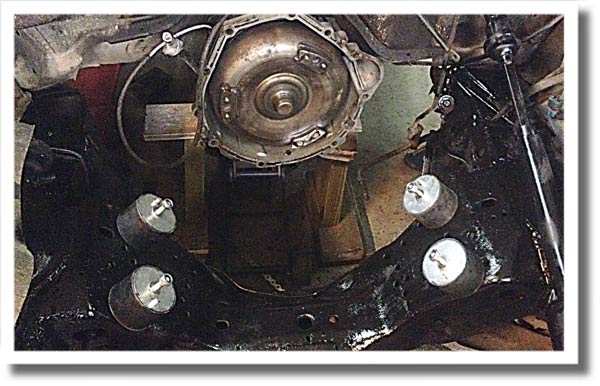

Engine and transmission mated for the first time. |

|

As the Mercedes converter is prone to fall out of the bellhousing, a strap was made to keep it in place while working the transmission under the car, and up on the floor jack. |

|

|

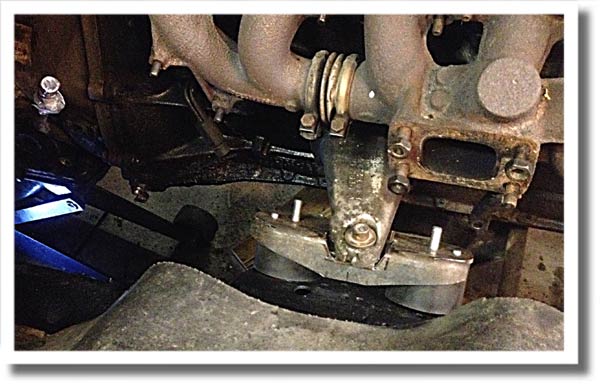

The Mercedes engine mounts are very bulky, so to avoid cutting into the cross member, Volvo engine mounts were purchased. Four of them to take the weight of the Mercedes diesel engine. |

|

Hoisted into the engine bay and bolted to the transmission with a couple bolts, the general fit of the engine is evaluated, and the placement of the engine mounts is decided on. |

|

|

Here the four engine mounts are fitted into their new holes in the cross member. |

|

The right hand side engine mount. Some tweaking and welding still to be done. |

|

|

Two bolts hold the turbo to the exhaust manifold in this pic.The compressor needs to be turned about 180 degrees. |

|

Unfortunately the lower A-arms (or control arms, whish bones...) really had to be removed to get access to the new engine mount bolts. Even then it was not the easiest of tasks to get the nuts going on the threads. |

|

|

The new engine mounts painted and ready to use. |

|

As the engine is bolted nicely to the car, it was time to fabricate a transmission mount. |

|

Go to NEXT page

THE MECHANICALS THE DETAILS ADJUSTMENTS

Back to KARKMOTUNING main page